Fond du Lac Box Manufacturer & Designer

Nelson Container manufactures corrugated shipping boxes for businesses in Fond du Lac. Call us at 262-250-5000 for a quote and learn more about our packaging services.

Our Milwaukee area packaging facilities serves Northern Wisconsin and the Fond du Lac area. We provide ready-made corrugated packaging in less than 48 hours, helping you respond to dynamic product demands. Contact us today for corrugated products customized to your business.

Ready Made Packaging in Less Than 48 Hours

Nelson Container Corp

W180 N11921 River Lane Germantown, WI 53022

262-250-5000

Shipping Box Options

Whether you know the box dimensions you need and are looking for a manufacturer or just have the product and are looking for the best shipping solution, we are here to help. We are able to make any box to your custom dimensions to keep your products safe during shipping from your business to the destination.

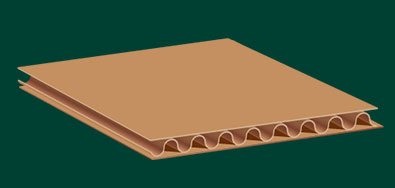

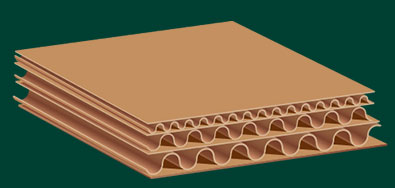

Single Wall Boxes

Max suggested load 120 lbs. Edge Crush Test 26-55 Mullen 150# - 350#

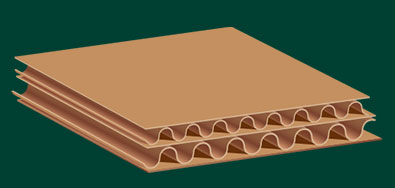

Double Wall Boxes

Max suggested load 180 lbs. Edge Crush Test 48-82 Mullen 275# - 600#

Triple Wall Boxes

Max suggested load 300 lbs. Edge Crush Test 67-120 Mullen 700# - 1300#Custom

Designed Packaging Today

We don’t only make boxes; we protect your investments. It's our job to make sure your goods are transported from business-to-business without any damage or delay. We take that job seriously, and ship out orders from our facilities at least once every day, shipping quality single-wall, double-wall, and triple-wall packaging to our business partners within 24 hours of order placement. Bulk corrugated packaging from Nelson Container provides a durable solution for storage or shipping.

Your product gets where it’s going without being harmed by the elements. Ask yourself these questions:

Will your product be traveling by boat? By train? By 18-wheeled truck? Will it be exposed to the crushing weight of other products in the same transport vehicle? Frozen? Passing through the most humid conditions? Moved from one vehicle to another in the middle of a rainstorm?

- Water-Resistant Films

- Rigid, Layered Walls

- Moister-Resistant Glues

Nelson Container chooses the package materials with your transportation method and route in mind.

Engineered Corrugated Solutions Across Markets

At Nelson Container, we engineer custom corrugated solutions for every industry. From fragile electronics to heavy machinery, our packaging experts craft precision designs using single, double or triple wall construction with tailored fluting. Our in-house ISTA-certified lab rigorously tests each solution, subjecting prototypes to vibration, impact, drop and atmospheric conditioning trials. We use CAD technology and rapid prototyping to perfect designs quickly. Our flexible manufacturing cells are adaptable, providing same-day production and multiple daily deliveries.

Nelson Container engineers industry-specific corrugated solutions for every packaging challenge, safeguarding your products and optimizing your supply chain.

Our corrugated expertise drives value in your sector.

Comprehensive

box and packaging solutions:

Package Design

There’s more to it than just cutting out a shipping box to fit your products. Our engineers use CAD software to design custom packaging solutions. Working from the measurements of your product, we choose the corrugated cardboard that offers the right amount of strength and custom design inner packaging to ensure your products arrive safely. We can even produce jumbo-sized boxes for oversized shipments. Our focus on Quick Response Manufacturing enables us to deliver boxes on-time, even with sub-24 hour lead times.

ISTA Testing.

The International Safe Transit Association (ISTA) sets standards for packages should perform to ensure their contents are protected while in transit. They are the world’s leading authority on package testing, and their testing methods set the standard. Nelson Container is pleased to offer an in-house ISTA test lab to ensure the packaging we design meets the high standards of the ISTA. With us, there’s no need to send your packaging to a third-party ISTA test facility.

Inventory Management

When you partner with Nelson Container, our Vendor Managed Inventory (VMI) ensures you’ll have the packaging you need even if you need it at unpredictable or irregular intervals. By granting Nelson Container access to your inventory management system, we can track your supply levels and know when we need to start making additional packaging for you. We ship directly to your facility and offer the option of pre-assembled packaging so you don’t need to have your employers assemble anything.

Protective Inner Packaging.

Fragile and temperature sensitive products need more than bubble wrap and a “Fragile” sticker to keep them safe from the inevitable jolts and drops encountered in transit. Nelson Container provides custom designed, lightweight foam inserts, partitions and anti-static, moisture-resistant treatments to keep your products safe. We even offer insulating layers for medical or food products that need to stay cool.

Package Assembly

With Nelson Container, you can have your custom packaging shipped pre-assembled and ready to use. There’s no need to have your employers folding cardboard into boxes, punching out handles, and inserting foam inner packaging—and there’s no chance of the packaging being assembled incorrectly. Your packages arrive and all you have to do is put your products inside them.

Quick Response Manufacturing.

Nelson Container runs at the speed of business, delivering packaging solutions under seemingly impossible deadlines. For over 20 years we’ve been on a mission to shorten manufacturing critical-path time (MCT) by implementing lean principles, improving internal communication, and becoming more responsive to shorter lead times. Today, we’re the fastest box manufacturer in Wisconsin.

Heavy-Duty Triple Wall Packaging

Nelson Container offers triple wall corrugated boxes for all of your shipping, storage and packaging needs. Triple wall boxes are often overlooked in favor of less expensive packaging options. Heavy-duty packaging allows you to fit more items in one container and save you money when shipping large quantities of merchandise. Unlike many single-wall packages, triple wall packages offer increased edge crush strength and puncture resistance. When you need to protect and transport heavy or fragile items, purchase triple wall corrugated packaging from Nelson Container.

Protective Inner Foam Packaging

Take a carton of eggs, and drop it on the floor. The carton is perfectly undamaged, right? But how do the eggs look?

Simply designing a container isn’t enough. Our containers protect your product from the elements encountered during transit AND from the product’s own specifications. We design the protective shell as well as any protective inner foam or inner corrugated board designs needed to keep your product stationary and safe.

Not every object fits perfectly in a rectangular container. Not every object has rectangular dimensions. Not every object sits still and unaffected during a cross-country trip in a train car. When your product has awkward dimensions, a hard-to-identify center of gravity, sharp corners, or other complicating aspects, you need Nelson Container.

Nelson Container’s Newest and Largest Box Making Machine

The Beast allows us to create large, jumbo or bigger corrugated boxes faster and cheaper than anyone else in or around Fond du Lac. Newly designed packages have a lead time of 48 hours and repeat packages are down to an astounding 24 hours.

Each corrugated box order is made to your exact specifications. We are able to use whatever types and grades of materials you need, with either stitched or glued joints to package your products.