WisconsinCorrugated Box Design Services

Nelson Container designs custom B2B packaging for companies with unpredictable orders of high-value products in need of agile package manufacturing.

Every Box is a Custom Box

At first glance, most boxes are four walls with a top and bottom with a single wall, double wall, or triple walls for added strength. It’s when you open the package you see evidence of the engineering genius put into packaging the product.

When our package specialists get the specific measurements (dimensions, weights, etc.) of your product, they analyze a variety of metrics to determine the best packaging solutions to keeping your product safe.

Even if two products look the same on the outside—shape, height, length, width, weight—the products’ insides may be different, and the internal design of the packaging must be specified. Their balance points may be incongruous. At Nelson Container, our engineers take every factor into account to customize packaging solutions for your requirements in the most cost-effective way possible.

Corrugated Box Design Process

Before creating your custom box we analyze the product's size, weight, shape and center of gravity to identify and prevent any issues that could arise during the shipping process. After this initial research process, we begin the three-step sample production process.

- Packages are designed with CAD software

- A CNC machine accurately cuts a sample

- The sample is assembled and tested rigorously

These sample designs are saved for future use enabling us to provide a 24-hour turnaround time for repeat orders. Our thorough testing process and fast turnaround times are only a few of the reasons our partnerships with businesses in Wisconsin and surrounding states like Illinois and Minnesota are so successful.

We Offer Safe Transit with

Custom Package Design

At Nelson Container, you come to us with a need for custom B2B packaging design, and our engineers develop unique packaging solutions based on your product's specifications:

- Solid exterior packaging guards your product against the elements

- Protective interior inserts strengthen your packaging and protect your product

- Timely deliveries keep your company on track to succeed

- Quality merchandise at wholesale prices

Foam Packaging Solutions in Bulk

Using foam inserts in your packaging will keep your products safe and secure during travel and storage. Made with a grooved pattern, these inner packaging supports offer a cushion against shock and impact. Adding more support on the sides of the container increases safety and security over foam packaging inserts alone. Utilizing the lightweight foam material, our packing inserts are great for bulk shipping on a budget. Ship with ease when you add foam insertions to protect your products.

Custom designed inner packaging is a large part of what makes us reputable and successful as a business. Anyone can put your product in a box. Nelson Container makes absolutely sure your product won’t be damaged while it's inside the box, and we get those boxes to you fast.

Custom Printing on Shipping Boxes

When you partner with Nelson Container to design your boxes we handle printing important labels and information directly onto the box. These labels and pictorials are important to ensure the safe handling of your products during the shipping process. Common things we print on boxes:

- Logos

- Handling instructions

- HAZMAT labels

- Containments (SKUs, quantities, bar codes, and more)

Types of Corrugated Shipping Boxes

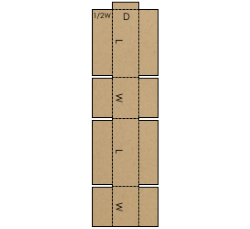

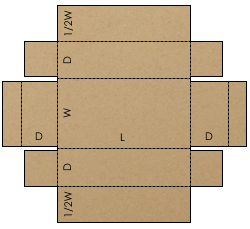

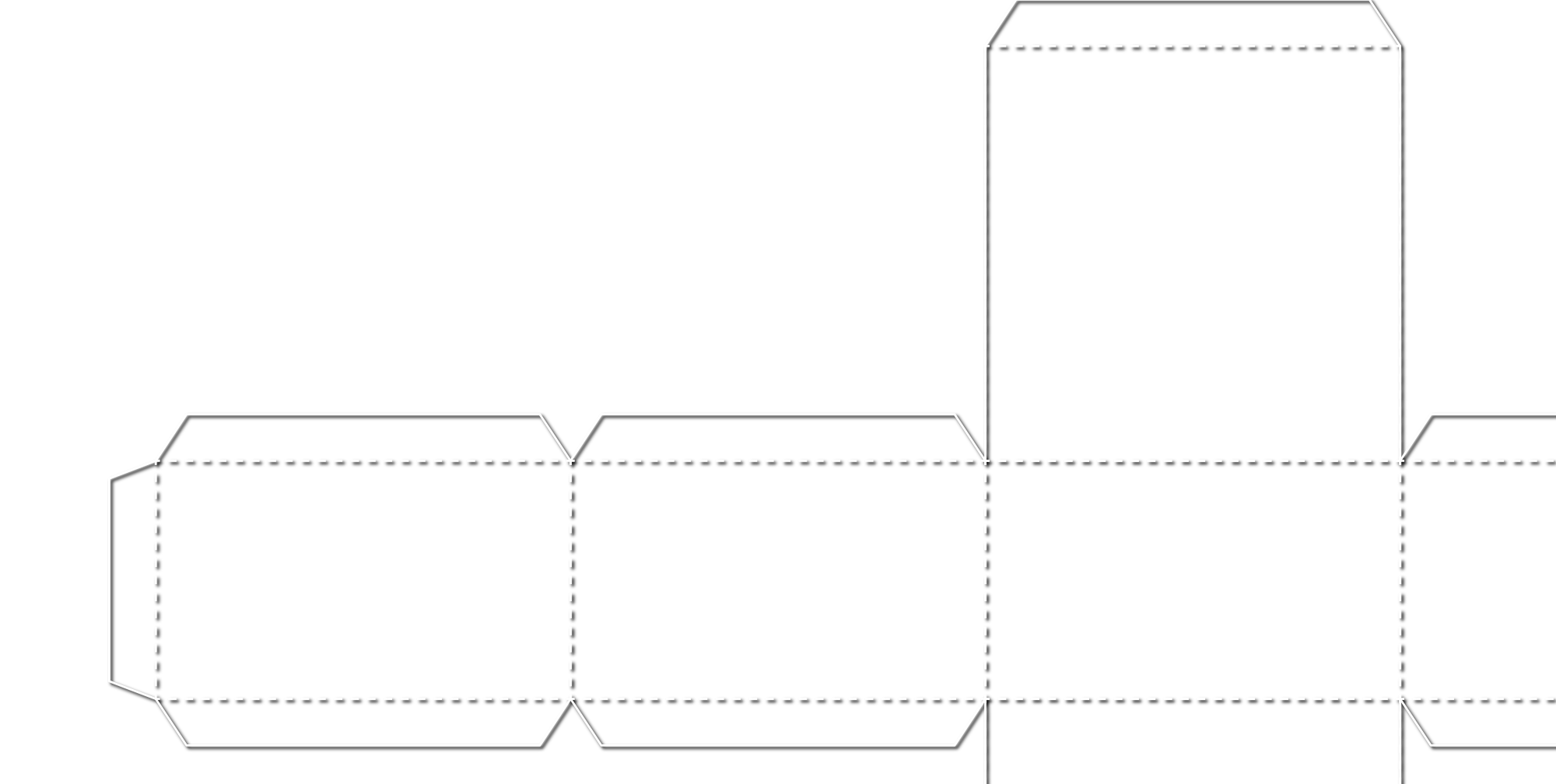

Regular Slotted Container (RSC) - 0201

Regular slotted containers are the most common of all box types. Their design makes them highly efficient for many different applications, and their manufacturing process produces almost zero waste.

- Great for Products in All Markets

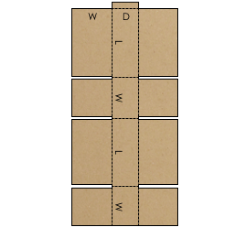

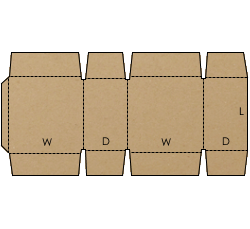

Full Overlap Slotted Container (FOL) - 0203

This style of box is almost identical to the RSC; the difference is the flaps. Flaps on FOL containers extend over the entire opening of the box, making them especially durable and resistant to rough handling. The overlapping flaps also provide extra strength for stacking on top, bottom, or sides.

- Best for Products in Industrial, and B2B Food Markets

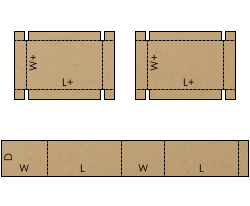

One Piece Folder with Dust Flaps (OPF) - 0415

OPF corrugated boxes are what you may want to use if you’re shipping printed circuit boards (PCBs), because the dust flaps will protect them from dust, and the individual cases aren’t heavy enough to merit more rigid structures. (You will want to consider your transportation type in the above scenario, to make sure you aren’t transporting these with heavier, loosely-packed items.)

- Best for Electronics Products

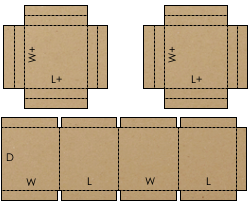

Wrap-Around Blank - 0406

These boxes are cut to the right dimensions, and then a sturdy product is placed on the corrugated board. The box is then formed around the product, with the joint being the final closure. When finished, wrap-around blank boxes are, more or less, RSC boxes turned on their sides, making insertion and removal of the product more convenient.

- Utilized in All Markets

Double Cover Container (DC) - 0310

Double cover containers are essentially tubes with caps on their ends. DCs are frequently used for packaging items too tall or heavy to easily be placed into boxes. One of the covers is placed on a surface, and the object it will contain is placed on that cover. Then the tube part of the box slides on over the top of the object, and the other cover is placed on top. These are commonly found with die cast parts or other heavy metal objects.

- Most Popular with Industrial Market Customers

Interlocking Double Cover Container (IC) - 0325

ICs are exactly like DCs, except for one difference; the lids interlock with the tube when you put the box together. The ease with which these packages fit large objects makes this a great option to use in when packaging washers and dryers and other large appliances. Moving these appliances is easier than if you were to try with a DC, because you can use the box as a sort of help when pushing the object to where it will be placed.

- Used for Industrial Markets

| Style | International Fiberboard Case Code | Preferred Ratio – L:W:D |

|---|---|---|

| RSC | 0201 | 2:1:2 |

| Telescope HSCs (0200) | 0320 | 2:1:1 |

| Telescope CSSCs (0204) | 0320 | 1:1:1 |

| CSSC | 0204 | 1:1:2 |

| Telescope Trays | 0301 | 1:1:0.25 |

| Full Overlap | 0203 | 2:1:4 |

*Flute profiles and the adhesives we use are both important parts of our corrugated package design choices

Multiple walls act as a buffer between the product in the packaging and its external environment, which may be extreme temperatures, humidity, winds, other tumbling packages, etc.

| Flute Type | A | B | C | E | F |

|---|---|---|---|---|---|

| Flutes/Foot | 33 | 47 | 39 | 90 | 125 |

Nelson Container combines flute profiles when necessary to achieve just the right amount of strength without having to waste material. This ensures you get the best packaging solutions for both your dollar and unique needs.

Flute Profiles and Walls

Flute profiles, walls, and the adhesives we use are all important parts of our corrugated package design choices. If a product is heavy, easily tipped, likely to be jostled during transit, or has points jutting out in various directions, choosing a double or triple-walled packaging is preferred over single-walled.

Most Common

Box Styles and Uses

A box is a box is a box, right? Wrong. There are many different types of boxes with varying strengths and usefulness for different products and methods of transport. The time an item sits in transit, the climate it will be exposed to, the type of transportation, and many more factors go into the choice of which kind of box to use and how to support each box’s weak points.

Specialized

Moisture-Resistant Adhesives

Some of the adhesives we use to keep our packages together are starch-based. Adhesives made using starch as a base aren’t particularly conducive to holding together in the presence of moisture. When we anticipate a package may encounter high humidity or other forms of moisture during transit, we switch to either a Moisture Resistant Adhesive (MRA) or a Water-Resistant Adhesive (WRA). The former is better suited for high-moisture environments and very brief, direct exposures to small amounts of liquids. The latter is rarely necessary, yet is useful for when we anticipate a package may be entirely submerged in a liquid.

Rapid Transforming corrugated

Low-Volume per SKU, No Problem

Nelson Container specializes in rapidly transforming corrugated boards and other materials into your custom business-to-business transit packaging. Our machine operators are able to change the settings on their machines very quickly, allowing us to accommodate low-volume per SKU orders especially well. Our QRM manufacturing process allows us to pass on the cost savings of wholesale pricing to our customers.

Effective communication is one of Nelson Container’s strengths. Interactions and invoices are easily understood and processed with the help of our online ordering system, eKban. Even if you change the specs of your product at the last minute, we change our design to meet your new requirements. Eliminate unnecessary overhead and mitigate the risk of on-time delivery failure. Choose Nelson Container as your full-service corrugated packaging manufacturer.

Need Jumbo Boxes?

The Beast is Ready

If you have large products to ship, Nelson Container has just the equipment to build an ideal shipping solution in 24 hours. Our Jumbo Flexo Folder Gluer machine (aka “The Beast”) enables us to produce large to jumbo-sized boxes with single to triple wall corrugation.

You might think custom-designed Jumbo-sized boxes would take longer to produce. Not at Nelson Container. We’re known for short lead and setup times, and our Jumbo boxes are no exception. The average lead time for a new package design is just 48 hours, while repeat orders can be completed in 24 hours.