ECT vs Mullen Test for Box Strength

Difference Between Edge Crush Test and Mullen Test

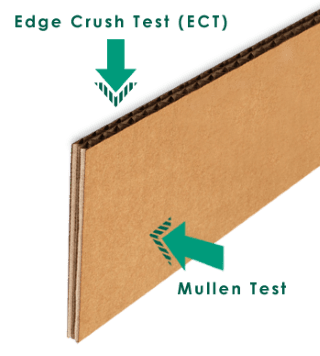

The Edge Crush Test rates how much weight can be stacked vertically on a box without damage and the Mullen Test rates how much force it takes to puncture a wall of the box. ECT rating is important to consider when stacking boxes, while Mullen rating is important for sharp & irregularly shaped items. See below for recommended ratings.

Mullen Test (Burst Test) for Box Strength

The Mullen Test (burst test) has been used for over 130 years to determine how resistant a box is to punctures. These days punctures from outside sources are a very prominent threat during transit when a box is moved.

Boxes are tossed from one conveyor belt to another and crash into other boxes of varying sizes, shapes, and rigidity. It is important to test the burst rating of your shipping boxes to ensure your products will arrive at their destination undamaged.

Nelson Container uses these tests often on the large- and jumbo-sized packaging produced on our new flexo-folder/gluer:

Edge Crush Test (ECT) for Box Strength

The edge crush test (ECT) tests how much weight can be stacked on top of a box without the edges being damaged. Common ECT ratings are 32 for single-wall boxes, 44-48 for double-wall boxes and 60-90 for triple wall boxes.

Modern production and shipping have changed drastically, and the testing methods we use to measure a package’s strength have changed accordingly. These days, much of the shipping is done as boxes on pallets, delivering wholesale goods from one business to another business (B2B). Testing the edge wall of a box for its stacking strength is the most sensible and reliable measure of how well the box will hold its form under the vertical weight during transit. Understanding the specifications of an ECT chart is relatively easy. If a corrugated container has a 55 ECT rating, it means that it can withstand a 55 lbs of pressure on the edges of the cardboard.

Edge crush testing is generally the test you want to be done when testing your package strength for B2B shipping, especially if the packages are medium- to small-sized and going to be stacked on top of one another. This is where corrugated provides a significant advantage.

Recommended Ratings Based on Weight

| Max. Suggested Load/Box | Min. Edge Crush Test | Mullen (Burst) Test |

|---|---|---|

| 35 lbs. | 26 ECT | 150# |

| 50 lbs. | 29 ECT | 175# |

| 65 lbs. | 32 ECT | 200# |

| 95 lbs. | 44 ECT | 275# |

| 120 lbs. | 55 ECT | 350# |

| Max. Suggested Load/Box | Min. Edge Crush Test | Mullen (Burst) Test |

|---|---|---|

| 100 lbs. | 48 ECT | 275# |

| 120 lbs. | 51 ECT | 350# |

| 140 lbs. | 61 ECT | 400# |

| 160 lbs. | 71 ECT | 500# |

| 180 lbs. | 82 ECT | 600# |

| Max. Suggested Load/Box | Min. Edge Crush Test | Mullen (Burst) Test |

|---|---|---|

| 240 lbs. | 67 ECT | 700# |

| 260 lbs. | 80 ECT | 900# |

| 280 lbs. | 90 ECT | 1100# |

| 300 lbs. | 112 ECT | 1300# |

Tested & Approved Triple Wall Packaging

Triple wall corrugated boxes are the heftiest boxes on the market. Designed to withstand heavy weight and protect delicate products, these boxes are the perfect solution for shipping fragile items. Adding protective foam inserts will ensure that your fragile products stay as safe as possible. All triple-walled packaging is tested and approved through the ECT and Mullen tests for strength. For large shipments, order our corrugated packages in bulk.

Nelson Container will even make your custom designed package official with ECT/Mullen BMC mark printing. Combined with our inner foam packaging, your products will be protected inside and out during transit.

Check out our ISTA Testing page for more package testing information.

What are

Edge Crush Tests and Mullen Tests Used For?

Both the edge crush test (ECT) and Mullen test are used to test the strength of a box, and both of these tests have their place in the world of packaging.

Lucky for you, Nelson Container has an in-house ISTA testing lab with both Mullen Test and edge crush test capabilities so we don't need to outsource to a third-party company. In-house testing saves time and money for us, and we pass those savings on to you.

"Partners" means we both benefit.

Small to medium-sized boxes that will be stacked on pallets are best tested using the ECT, and large to jumbo-sized boxes loaded directly onto trucks for quick B2B shipping are best tested using the Mullen Test.